Brief description

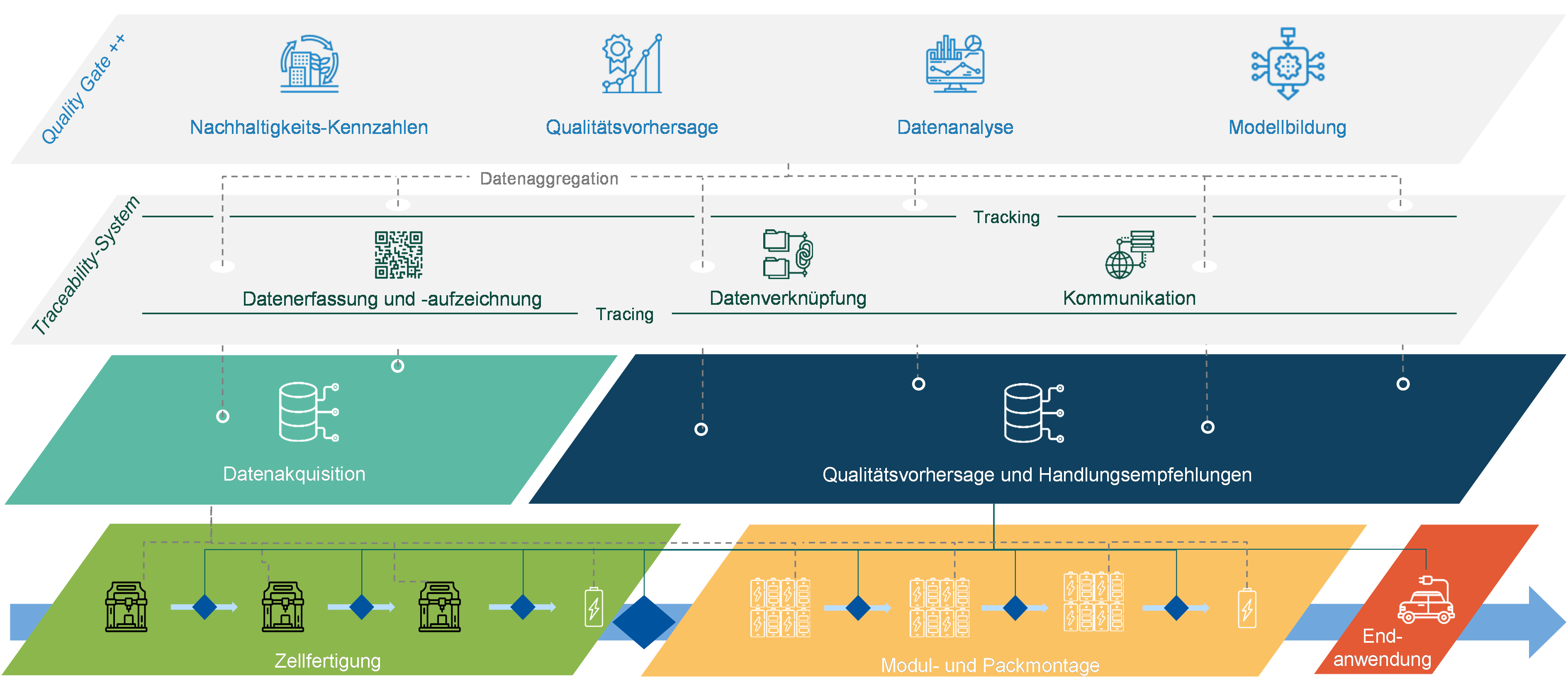

A cell-accurate transfer of process and quality data from production and the integration of (PQ) in quality gates along the entire battery production process through to the end application (Figure 1) should enable a reduction in the inspection effort in the area of incoming and outgoing goods inspection in the battery value chain.

The main objective of the project is to reduce physical inspection scopes in the battery value chain by up to 80%, especially for incoming and outgoing goods inspections in module and pack assembly. The physical inspections at quality gates are to be eliminated by developing a trustworthy PQ model that achieves TRL 7 as part of the project. The necessary database will be created using a suitable traceability system. In addition, the derivation of sustainability indicators from already collected process and quality data is to be made possible and their presentation and optimization implemented using an online process model.