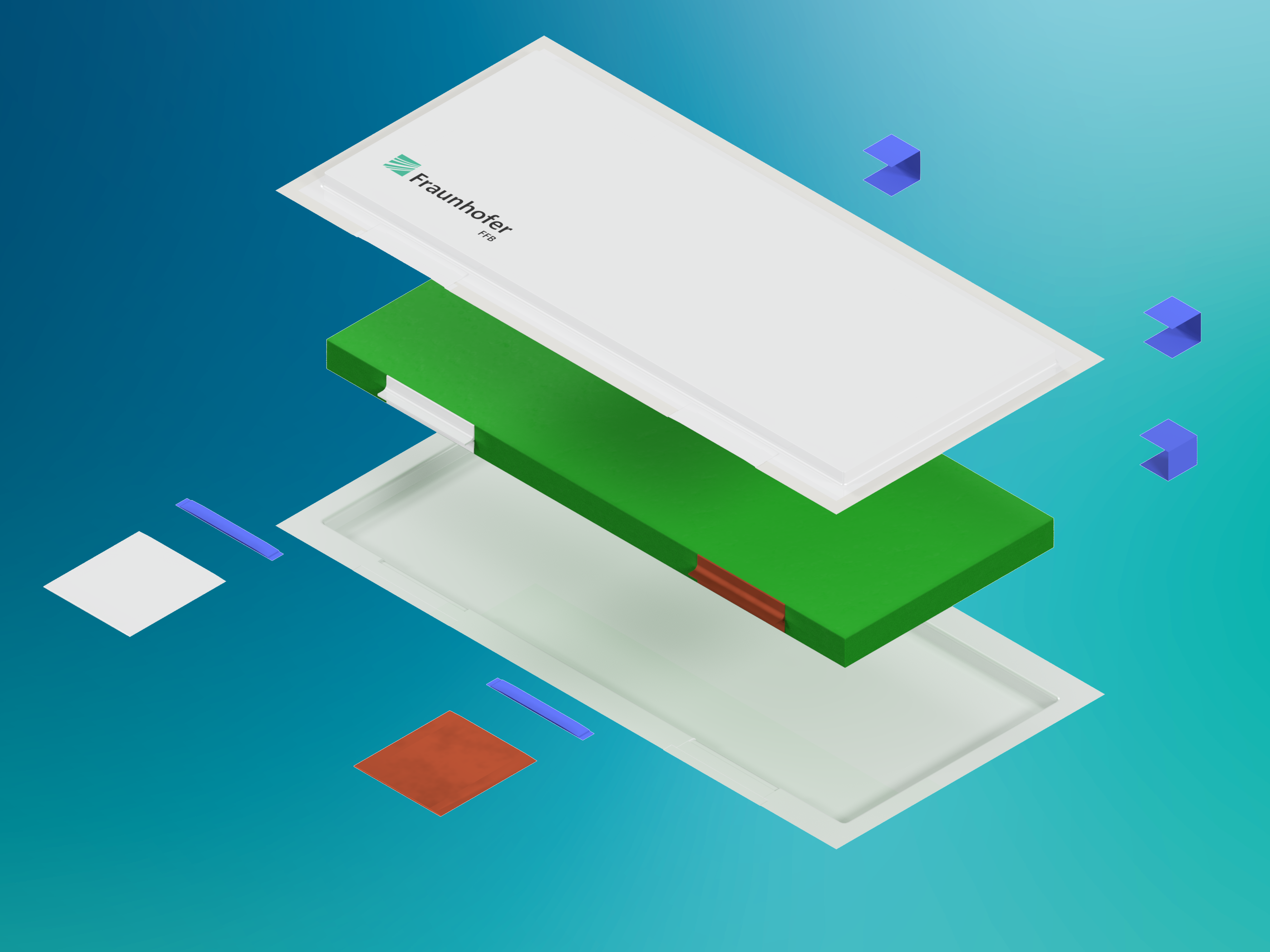

The structure of prismatic cells resembles that of a pouch cell, except for the hard case that serves as its outer housing. These cells can hold one or more stacks of cells or flat coils, with arrester flags connected to terminals embedded in the cover. This design can be more complex than that of a pouch cell, as it can accommodate multiple cell composites. Additionally, electrodes can be stacked or wound, similar to round cells. Once the cell stack is packed into the housing, it is filled with electrolytes and sealed. Advantages and disadvantages of the pouch cell

- (+) Safety and thermal management

- (-) Power and energy density

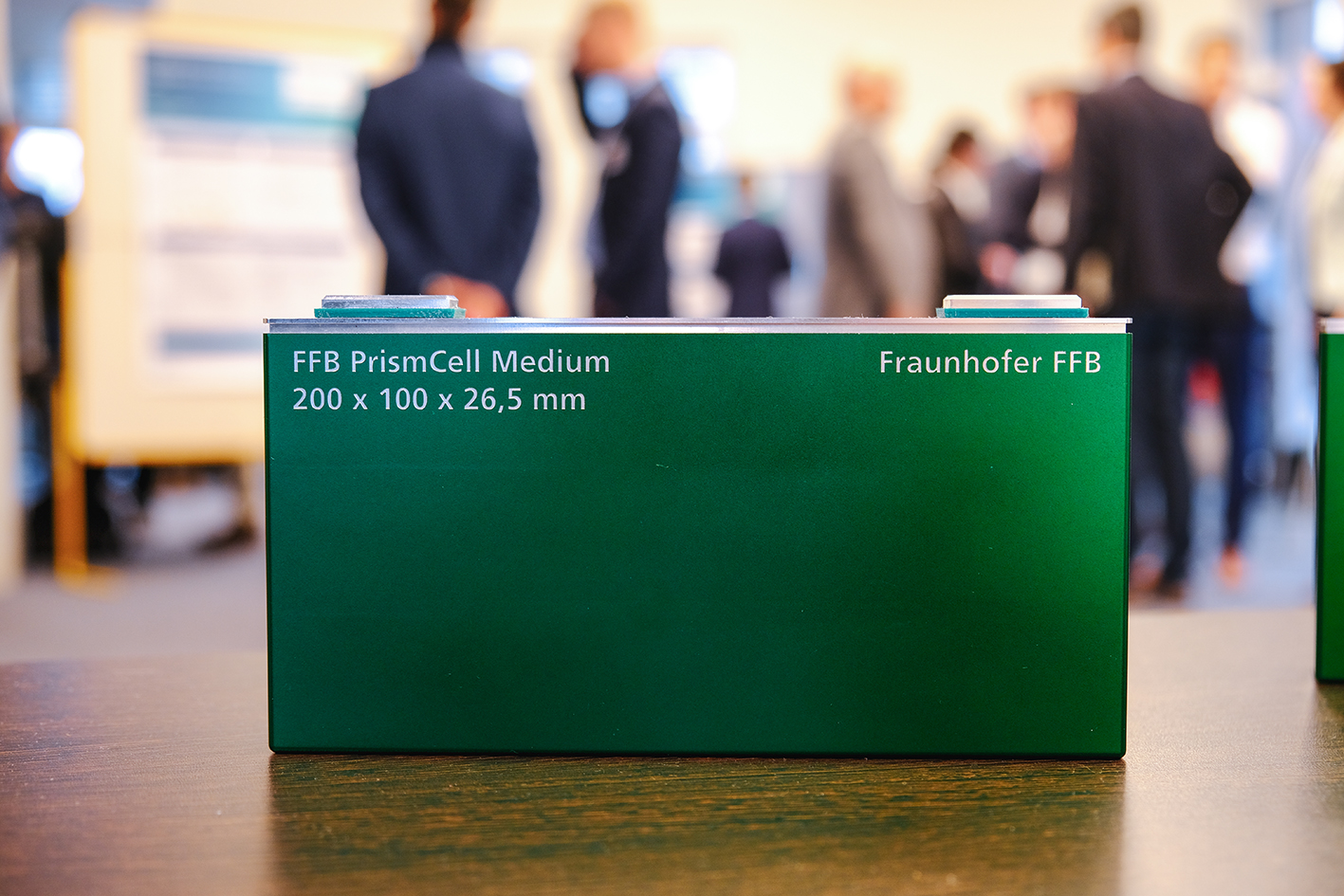

FFB PrismCell medium and FFB PrismCell Large

Fraunhofer FFB will produce two models of the prismatic cell, which differ in dimensions: The FFB PrismCell medium will measure 100mm shorter and also a few millimeters less in width than the FFB PrismCell Large. With these two sizes, we cover the most important application areas of prismatic cells.

- FFB PrismCell medium: stationary storage systems

- FFB PrismCell large: E-mobility

For each model, there will be a "high power" and a "high energy" variant, which differ from each other in the cell chemistries used.

We anticipate creating the initial prototypes by the summer of 2023. The Large model should be ready for production by 2025 at the "FFB PreFab," while the "FFB Fab" will be responsible for the Medium cells. By combining the pouch cell and prismatic cell, we can take advantage of their synergy and use cell stacks created on the pouch line for prismatic cell production at the "FFB PreFab."Research focuses on the prismatic cell the contacting system, safety elements, lid assemblies, production optimization, and the usability of the results obtained here for new cell chemistries (e.g. sodium ions and ASSB).