Whitepaper

White paper examines global extraction, dependencies and future potential of lithium

Lithium is an essential raw material for the production of modern batteries used in electric vehicles, smartphones, and laptops. In the current white paper “Battery Raw Material Lithium,” Fraunhofer FFB examines global lithium deposits and industrial extraction processes, highlights ecological impacts, and identifies potential for sustainable production and recycling strategies.

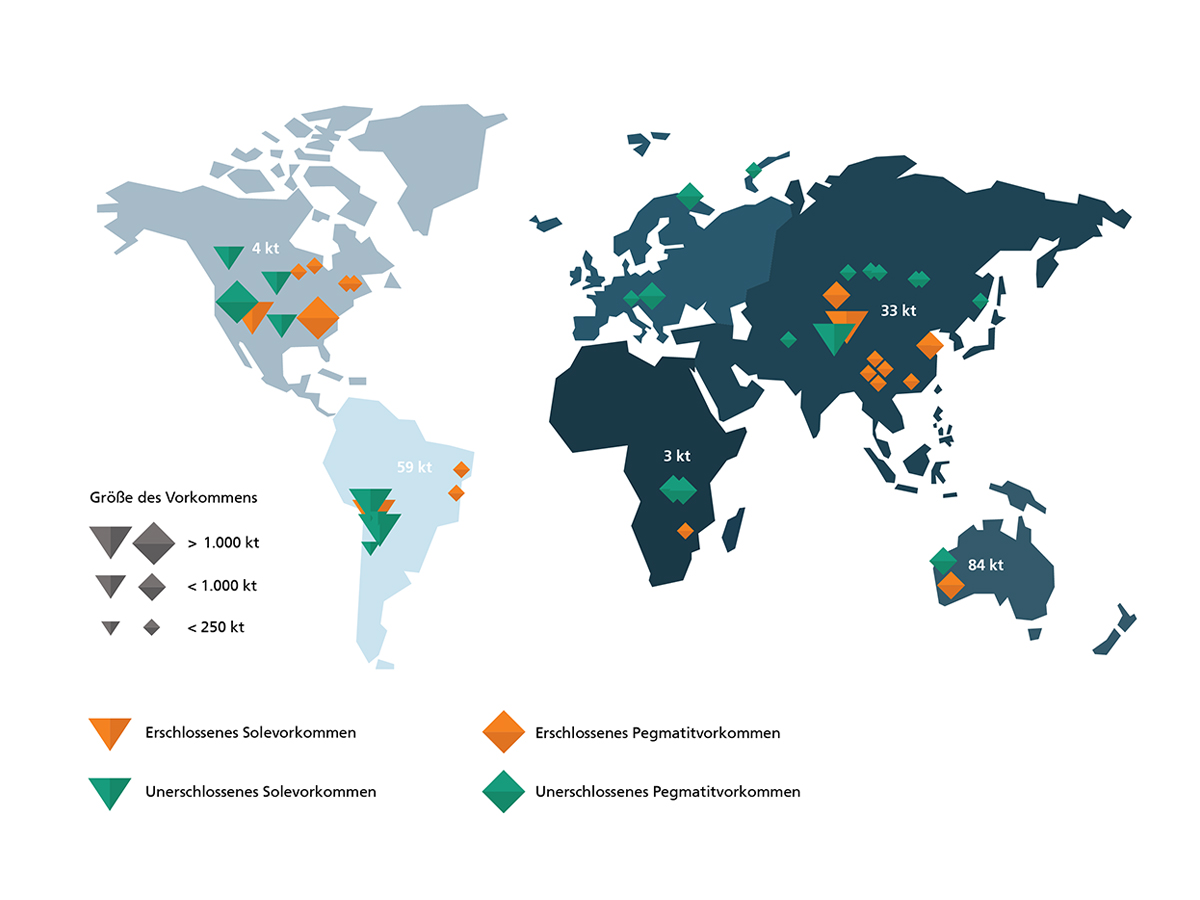

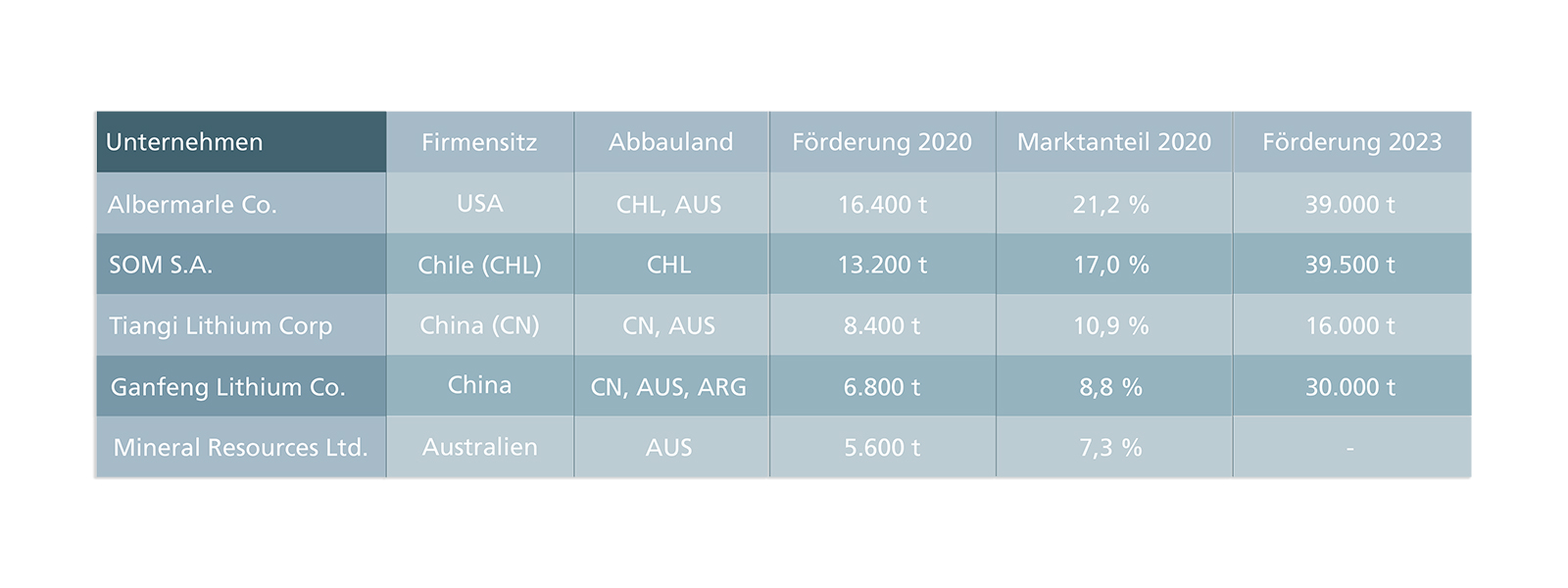

Münster. According to current calculations, six to eight kilograms of lithium are needed to produce the batteries for a single electric vehicle. Currently, 74% of the world's lithium comes from Australia and Chile, but only a few companies control the majority of global production. These include “Tianqi Lithium” (China) and “Albemarle” (USA). Europe, on the other hand, is almost 100 percent dependent on imports and has the smallest share of global reserves at just 2.5 percent. The Whitepaper shows which processes are currently used to extract lithium and the environmental challenges associated with them.

Two processes for lithium extraction

“There are currently two common production processes for the manufacture of lithium carbonate, one of the most important commercial products of lithium,” explains Dr. Daniel Slak, Sustainability Manager at Fraunhofer FFB. The first process is based on extraction from saline brines, primarily in South America and China. Solar energy is used for evaporation before the lithium is precipitated as lithium carbonate and purified.

The second process dominates the global market with around 60 percent. Here, lithium is extracted in the form of rock in traditional mining and chemically processed. Both processes have their respective challenges. For example, brine extraction requires considerable amounts of water. Mining, on the other hand, produces large quantities of overburden, requires a lot of energy, uses more chemicals and involves long transportation routes. “This form of extraction is significantly more energy-intensive,” emphasizes Slak.

Recycling as the key to a circular economy

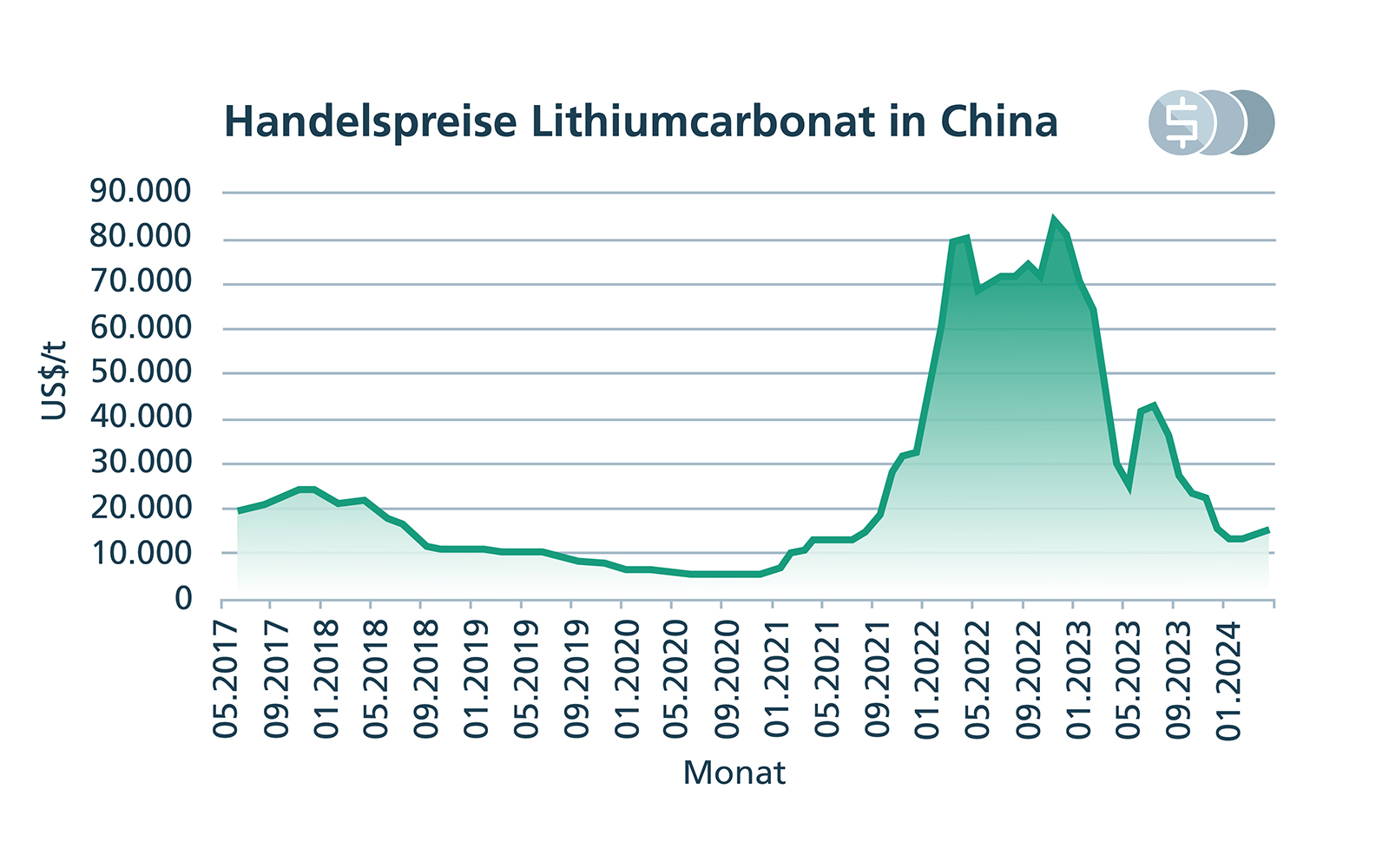

The Whitepaper explains in detail how the individual processes differ. With a view to a European circular economy, the recycling of battery raw materials plays a central role. It is seen as a strategic key to reducing dependencies on global supply chains and preventing potential supply bottlenecks. The reduction of transport routes through recycling within Europe is also highlighted as an advantage. “Increasing electrification, the expansion of e-mobility and European legislation will noticeably drive the recycling market in Europe,” explains Dr. Florian Degen, Head of Strategy and Business Development at Fraunhofer FFB. However, as vehicle batteries have a lifespan of 10 to 15 years, the first relevant quantities of secondary raw materials will not be available until 2035 at the earliest.

Industry needs strategies for sustainably securing raw materials

"The market is growing faster than the availability of recycled materials. At the same time, many recycling technologies are still in their infancy," emphasizes Slak. “This shows how important it is to develop industrial solutions.” The analysis sees further levers for improving raw material security in investing in in-house refinery capacities and developing strategic partnerships with countries rich in raw materials, among other things.

Whitepaper provides impetus for research and practice

The Fraunhofer FFB Whitepaper is based on current specialist publications, production figures from the relevant companies and raw material overviews from various countries, as well as ecological databases. It is aimed at interested parties from industry and science who are involved in battery cell production, raw material strategy, sustainability or recycling technologies. The analysis provides reliable data, practical comparisons and impulses for future technologies and funding strategies.

Last modified: