Press release

“KOOP”: Fraunhofer FFB to Accelerate Production Technology Industrialization

The Fraunhofer Research Institution for Battery Cell Production FFB has started the new “KOOP” project together with the Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University and mixing technology specialist “hs·tumbler”. The aim of the project, which is funded by the German Federal Ministry of Research, Technology and Space, is to accelerate the industrialization of innovative production and battery technologies. For the next three years, the partners will deal with the systematization of collaboration between innovative companies or research institutions and the Fraunhofer FFB on the basis of a specific use case.

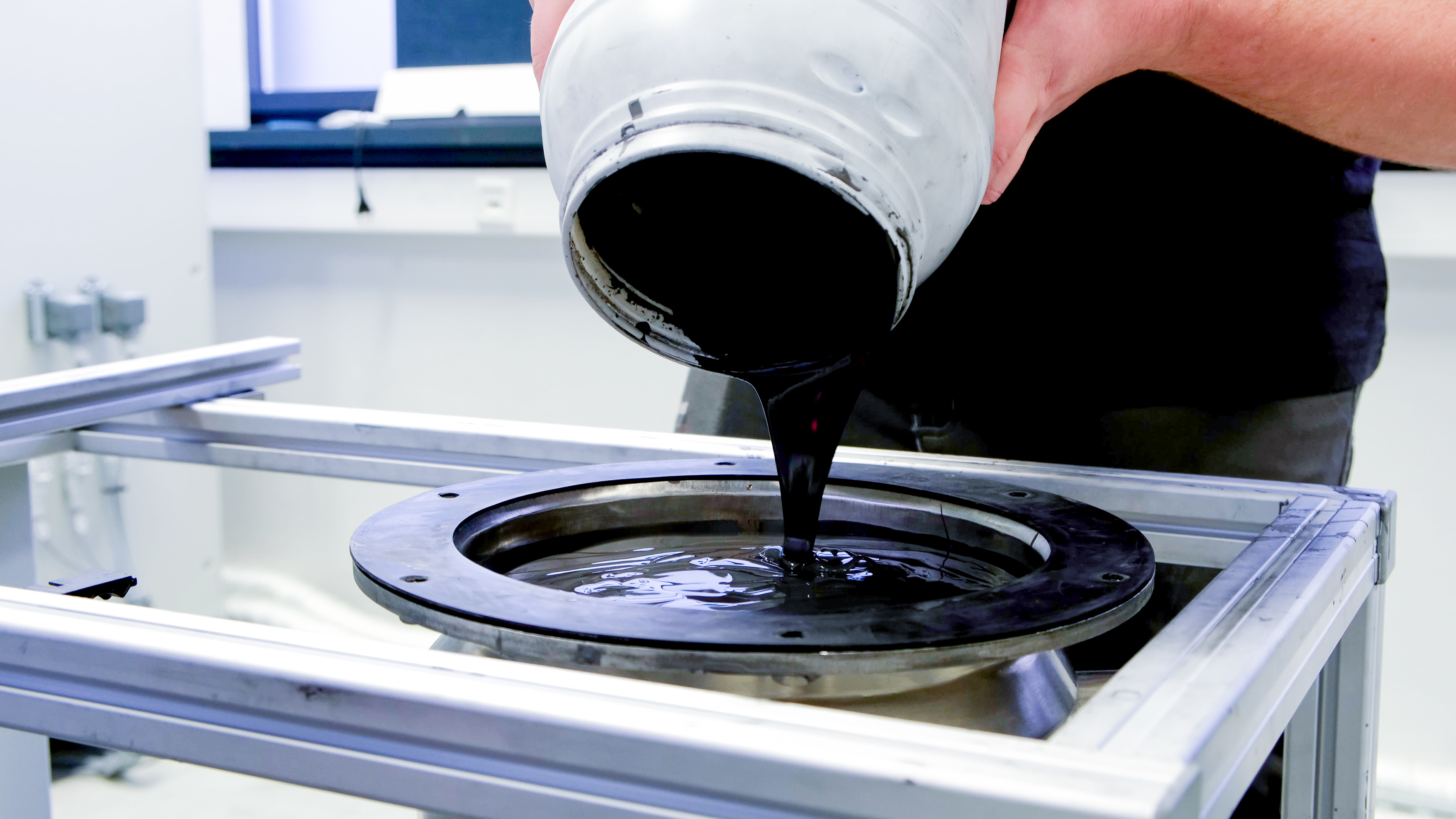

Münster. To this end, PEM and Fraunhofer FFB have developed a “Highly Cooperative Scaling” approach. This method is intended to avoid the delays that usually occur at medium technology maturity levels when transferring new production technologies from laboratory scale to scaled application. “Challenges in knowledge and data transfer, as well as previously uncoordinated financing and scaling strategies, lead to idle times ranging from six months to several years,” says FFB Director Professor Achim Kampker. As part of a specific application scenario, the project is dedicated to product and process development for a sodium-ion battery, concentrating on a hard carbon anode, which is to be produced using the trajectory mixing method.

“Sodium-ion technology has enormous potential to reduce our dependence on critical raw materials while promoting sustainable battery cell production in Europe,” says Dr. Moritz Schaefer, research associate at Fraunhofer FFB. “Through highly cooperative scaling, we are creating the conditions to transfer this future technology from the laboratory to industrial application more quickly.”

Innovation transfer through close cooperation

“Highly Cooperative Scaling" is intended to establish a systematic exchange of personnel, data, and management between innovators and Fraunhofer FFB. This will enable a rapid and comprehensive transfer of experience and expertise right at the production facilities. “We are thus creating a common database that enables the rapid and secure exchange of information between partners, paving the way for the accelerated industrialisation of new technologies,” says Dr. Moritz Schaefer. The data platforms are intended to minimise knowledge loss at the interface between innovators and Fraunhofer FFB, while enabling access to all product and process development data. Additionally, a management group from the institutions is developing a joint scaling and transfer strategy that is updated regularly.

The “KOOP” project is intended to serve as a blueprint for “Highly Cooperative Scaling” in collaboration with Fraunhofer FFB and to make an essential contribution to the industrialization of the sodium-ion battery technology as well as the trajectory mixing process. According to the project partners, the procedure has the potential to reduce energy consumption by at least 50 percent compared to conventional mixing methods.

Last modified: