Blog article

Project "AutoBot": Optimised battery cell testing

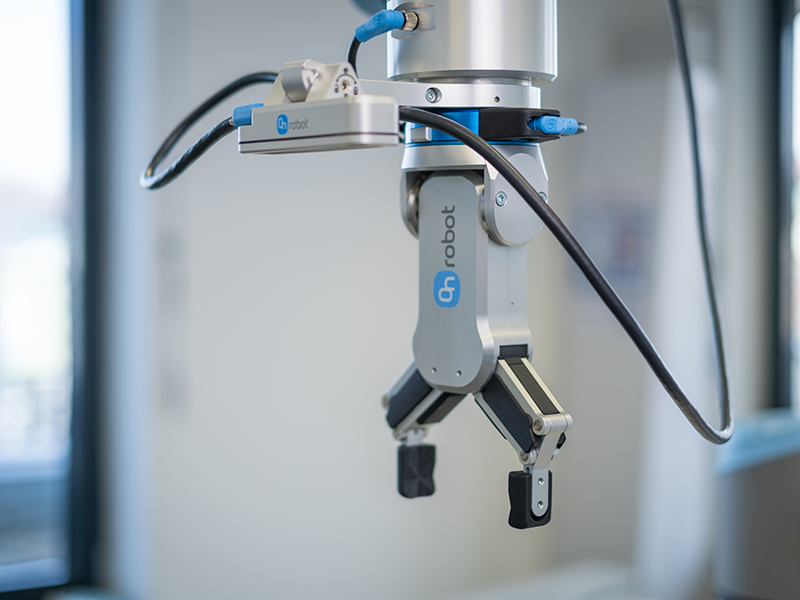

In autumn 2022, Fraunhofer FFB launched the project "AutoBot" in collaboration with the Institute for Power Electronics and Electrical Drives (ISEA) at RWTH Aachen University. Since then, significant progress has been made: The announced robotic arm is now in use at Fraunhofer FFB. It is undergoing extensive tests there before being integrated into the fully automated battery test bench at ISEA in Aachen in summer 2024.

The robotic arm is a key component of an automated test station designed to ensure continuous throughput and consistent test criteria in battery cell characterisation. By gripping the delivered battery cells and checking them for the various requirements in several passes, the robot examines different parameters such as dimensions and weight, but also the behaviour under load and long-term use. In this way, the robot arm acts as a handling system for the automated testing of battery cells within a test bench. The use of a Robot Operating System (ROS), an open source tool, facilitates the commissioning of the robot by visualising the processes in a digital space. Even before the robot was procured, the ROS data could be mapped in a digital process simulation. This can be used to test procedures and processes before they are subsequently transferred to the physical robot in a real environment.

Step-by-step integration of battery handling

The project team prepares all the necessary components to integrate them into the test bench at ISEA. This includes programming the robot as well as managing and controlling the processes.

Programming the robot

Previous robot processes were programmed and simulated using the ROS software. In the first step, a "matching" is now carried out in Münster in which the simulation is transferred to the physical robot. Deviations are identified and subsequently rectified.

Setting up the process control system

In addition to controlling the robot, a network of all the necessary digital and physical components is set up. A process control system monitors and controls the time of command execution - i.e. the type of command to be executed and the recording and storage of the measured data in databases. The ability to transfer programmes independently of the system makes it possible to transfer the same control system to a robot from another manufacturer.

Camera system

In addition to the components mentioned, a camera system is integrated into the test bench to enable the robot arm to recognise battery cells independently. This helps to reduce the susceptibility to errors and increase process stability.

Quality already in the box

Another component of the research project is the development of a goods carrier for transporting lithium-ion battery cells with integrated data recording. The transport box makes it possible to record the necessary safety and quality data during shipping and thus close the gap to a holistic inspection.

The robot arm therefore plays an important role in automation and, in addition to efficiency, also promotes the comparability of results.

Last modified: