IDEEL project achieves breakthrough in laser drying

Breakthrough in laser drying: IDEEL project demonstrates scalability for efficient battery cell production

Electrode-drying using the roll-to-roll process (R2R) has been one of the most cost- and CO2-intensive manufacturing steps in the production of lithium-ion batteries to date. A laser-assisted R2R drying process, which was developed as part of the IDEEL research cooperation, could change this in the future. It combines conventional, oven-based convection drying with laser drying based on high-power diode lasers and reduces the drying time by over 60 percent while maintaining the same quality of results.

Münster. In the industrial production of lithium-ion batteries, electrode drying was previously one of the most critical sub-processes. The high energy and time consumption and the considerable amount of space required made the drying of the active paste (slurry) applied to a current conductor foil using the roll-to-roll process (R2R) one of the most cost- and CO2-intensive manufacturing steps in the entire battery production process. Against this background, the IDEEL (Implementation of Laser Drying Processes for Economical & Ecological Lithium Ion Battery Production) research project, which was completed on December 31, 2024 after a three-year term, looked for alternative drying processes using highly efficient large-area laser irradiation. The project was supported by the Federal Ministry of Education and Research as part of the Battery 2020 funding program and was carried out under the leadership of Laserline GmbH. The Fraunhofer FFB works together with the Production Engineering of E-Mobility Components (PEM) at RWTH Aachen University, Coatema Coating Machinery GmbH, Optris GmbH, the Fraunhofer Institute for Laser Technology (ILT) and the Münster Electrochemical Energy Technology (MEET) Battery Research Center at the University of Münster.

Development and Optimization of Laser Drying as the Project Focus

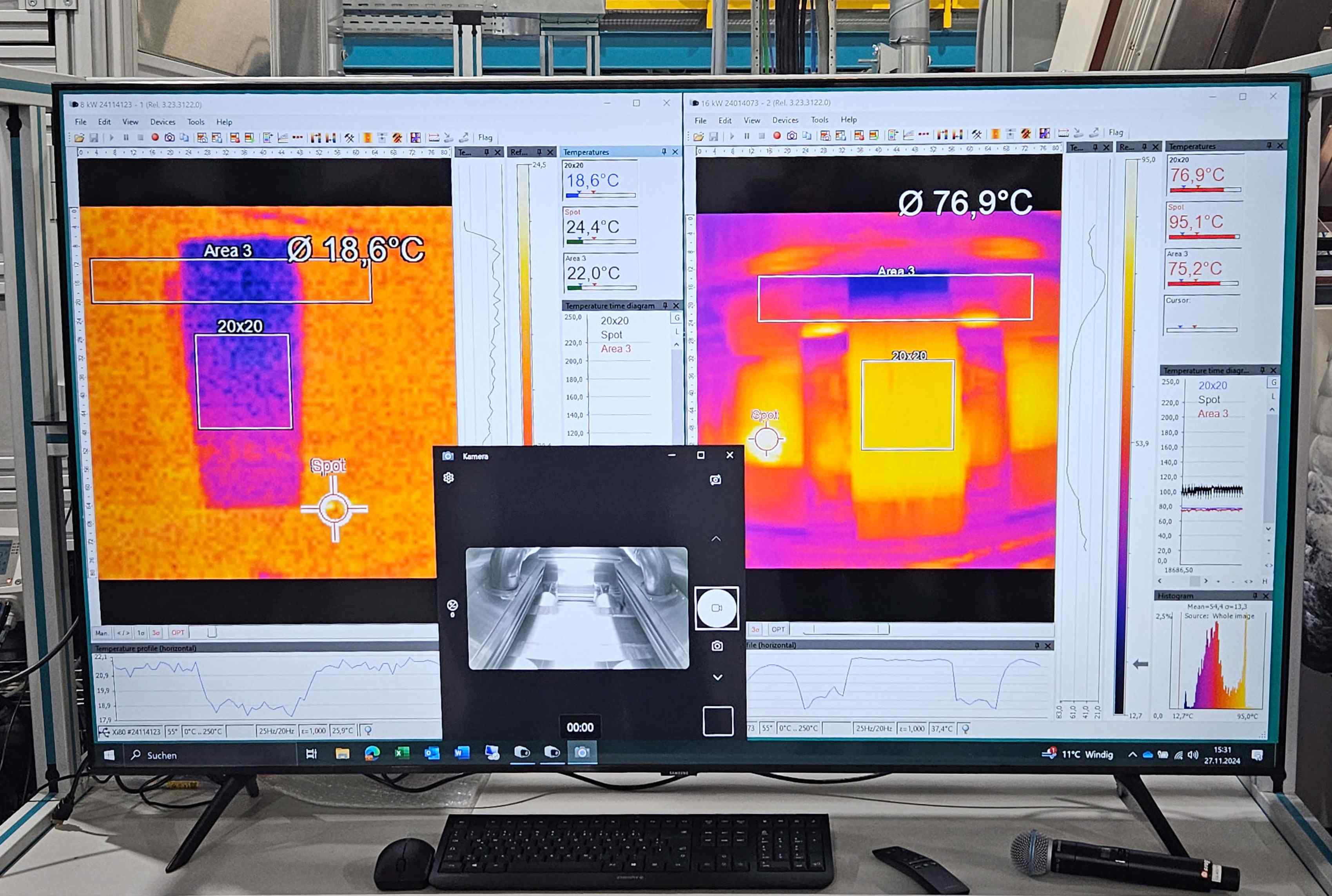

The focus of the IDEEL research collaboration was initially the development and step-by-step optimization of an appropriate laser drying process. For this purpose, new materials for anode and cathode coatings were specifically designed for laser applications, and, among other things, aqueous formulations based on graphite, lithium iron phosphate, and silicon-graphite were successfully tested (PEM of RWTH Aachen University, MEET Battery Research Center of the University of Münster). A high-efficiency diode laser system with an electrical efficiency of over 50 percent and a new processing optics with coaxial thermography coupling and a rectangular laser spot over 0.5 meters wide (Laserline) was used as the heat source. A highly integrated thermography camera with industry-PC-compatible data output was developed for contactless, automatic process monitoring and control, ensuring a constant adherence to the target temperature even with varying web speeds and coating thicknesses (Optris, Laserline, Fraunhofer ILT). Based on these system components, a modular laser drying unit with a specialized air concept and custom double-chamber wide-slot nozzles for the fast and secure application of water-based battery slurries (Coatema) was developed as a demonstrator. Within this demonstrator, the laser-based R2R drying process was scaled to industry-standard feed speeds, and the optimal process configuration was determined and validated (Fraunhofer ILT, Fraunhofer FFB).

Hybrid Process Enables Industrial Scaling

Since the drying process requires not only heating but also mass transport through air exhaust, the most technically and economically promising approach was the realization of a hybrid configuration with hot air and laser modules. In this R2R process configuration, the laser drying is used for rapid heating and pre-drying of the slurry, while the downstream convection oven extends the temperature holding time and finalizes the drying of the active paste. This approach allows the benefits of the new process to also be utilized in existing plants, which can then be retrofitted with laser modules. The exploration of technical optimization potentials is thus linked to the sustainable use of investment goods. In this sense, the project participants developed an innovative hybrid drying system, which for the first time achieves a web speed of 30 meters per minute and reduces drying times by more than 60 percent. Moreover, the laser booster at the beginning of the process halves the required oven length, saving valuable process space and significantly reducing the need for energy-intensive drying rooms. The operational costs of the drying process decrease overall by 20 to 30 percent, and the reduced oven operation, while simultaneously utilizing the equipment until the end of its life cycle, significantly improves the CO2 balance. Thus, the new approach enables more economical and climate-friendly processes, which also significantly improve the economic and ecological overall balance of battery production.

Studies Show Equivalence of Results at Increased Throughput

In terms of process results, the new hybrid process is not expected to have any disadvantages. Experimental investigations by Fraunhofer ILT, PEM of RWTH Aachen University, MEET Battery Research Center, and Fraunhofer FFB showed that the results of the hybrid drying process are on par with those of conventional convection drying. Despite the increased throughput rate, adhesion, residual moisture, electrical conductivity, and electrochemical properties are at least equally good. The industrial relevance of the newly developed process has thus been fully demonstrated. The hybrid process developed within the IDEEL project will therefore be integrated into the work of Fraunhofer FFB, which is to be expanded into the development center for modern battery cell production for Germany and its European partners.

Studies Show Equivalence of Results at Increased Throughput

In terms of process results, the new hybrid process is not expected to have any disadvantages. Experimental investigations by Fraunhofer ILT, PEM of RWTH Aachen University, MEET Battery Research Center, and Fraunhofer FFB showed that the results of the hybrid drying process are on par with those of conventional convection drying. Despite the increased throughput rate, adhesion, residual moisture, electrical conductivity, and electrochemical properties are at least equally good. The industrial relevance of the newly developed process has thus been fully demonstrated. The hybrid process developed within the IDEEL project will therefore be integrated into the work of Fraunhofer FFB, which is to be expanded into the development center for modern battery cell production for Germany and its European partners.

Last modified: