Background and motivation

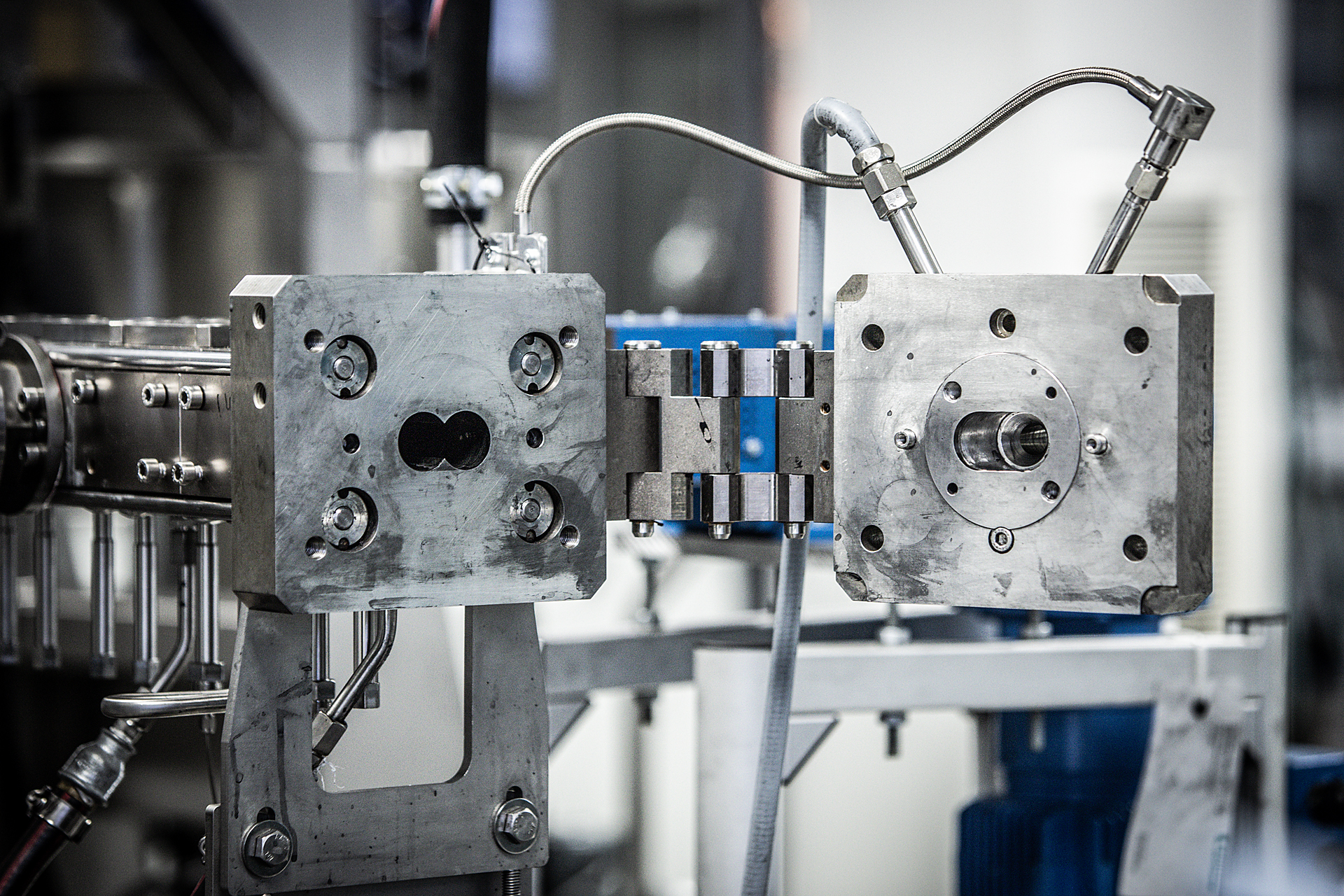

The battery market offers diversification opportunities for many companies: Be it in the production chain or in the life cycle. Our project partner is making the transition from a product-centric to a customer-centric organization in order to be able to offer its customers holistic solutions in the field of battery production. However, this change can only be successfully managed with a deep understanding of customer processes. To further strengthen its competitive position, KraussMaffei is considering expanding its business activities into the battery sector. At the same time, KraussMaffei has extensive experience in plastic extrusion, which is why the extrusion of electrode slurries was chosen as a focus.