The challenge: intransparent sourcing costs, uncertainty in planning and pressure on supply chains

The demands on battery cell production are increasing rapidly: raw material prices fluctuate, scaling is capital intensive and technological changes make it difficult to predict costs and make informed investment decisions. Added to this are unclear emissions targets and growing demands for sustainability and security of supply. Companies are under pressure to combine reliable data, strategic expertise and scalable production concepts before efficiency and competitiveness are lost.

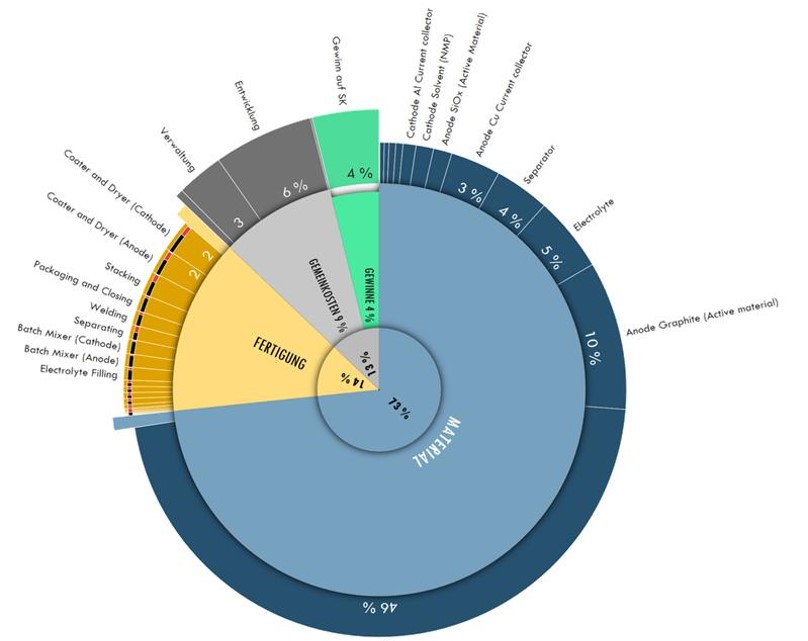

Cost transparency in the battery sector as a competitive advantage in sourcing

Fraunhofer FFB and Kerkhoff combine expertise in battery materials, battery concepts and production processes with years of experience in supply chain and sourcing optimization. The jointly developed cost model gives companies a decisive competitive advantage to optimize prices in battery cell purchasing. In addition to data-based cost analyses, the offer also includes design-to-cost.