The EU Battery Regulation and the Battery Passport

In addition to a company's intrinsic desire to become more environmentally friendly, political regulations set the direction for sustainability management. At both European and national level, there are more and more guidelines and laws that oblige companies to act sustainably. For example, companies that employ more than 500 people and are listed on the stock exchange must prepare sustainability reports. There are also regulations in the battery industry that anchor ESG goals in the corporate strategy.

In order to strengthen the internal market and promote the circular economy for batteries, the European Commission has issued a Battery Regulation, which came into force in August 2023. It replaces the previous Battery Directive, which did not contain any regulations on the performance, service life, emissions or origin of battery cells. The new regulation is a cornerstone of the European Green Deal, which aims to make Europe the first climate-neutral continent.

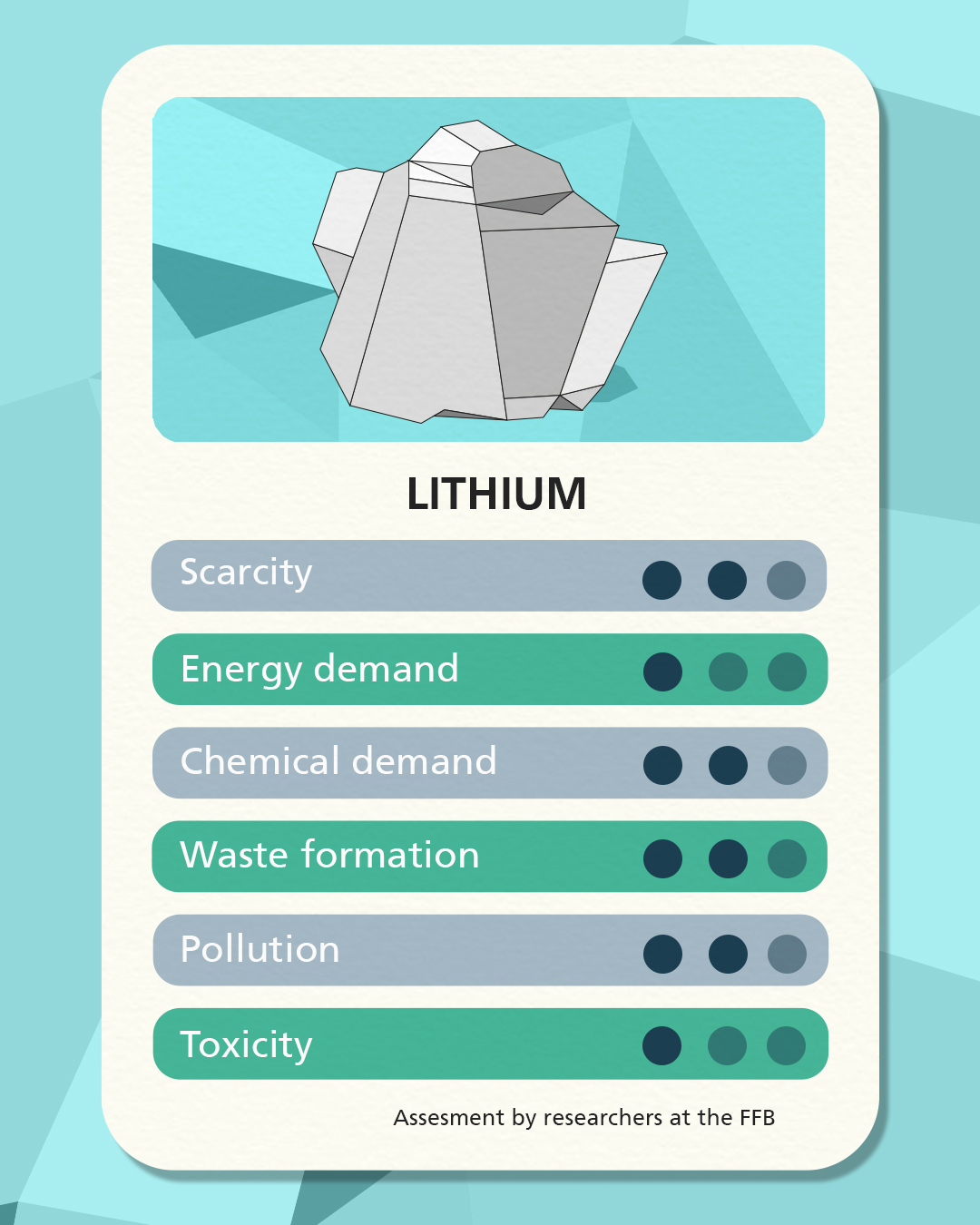

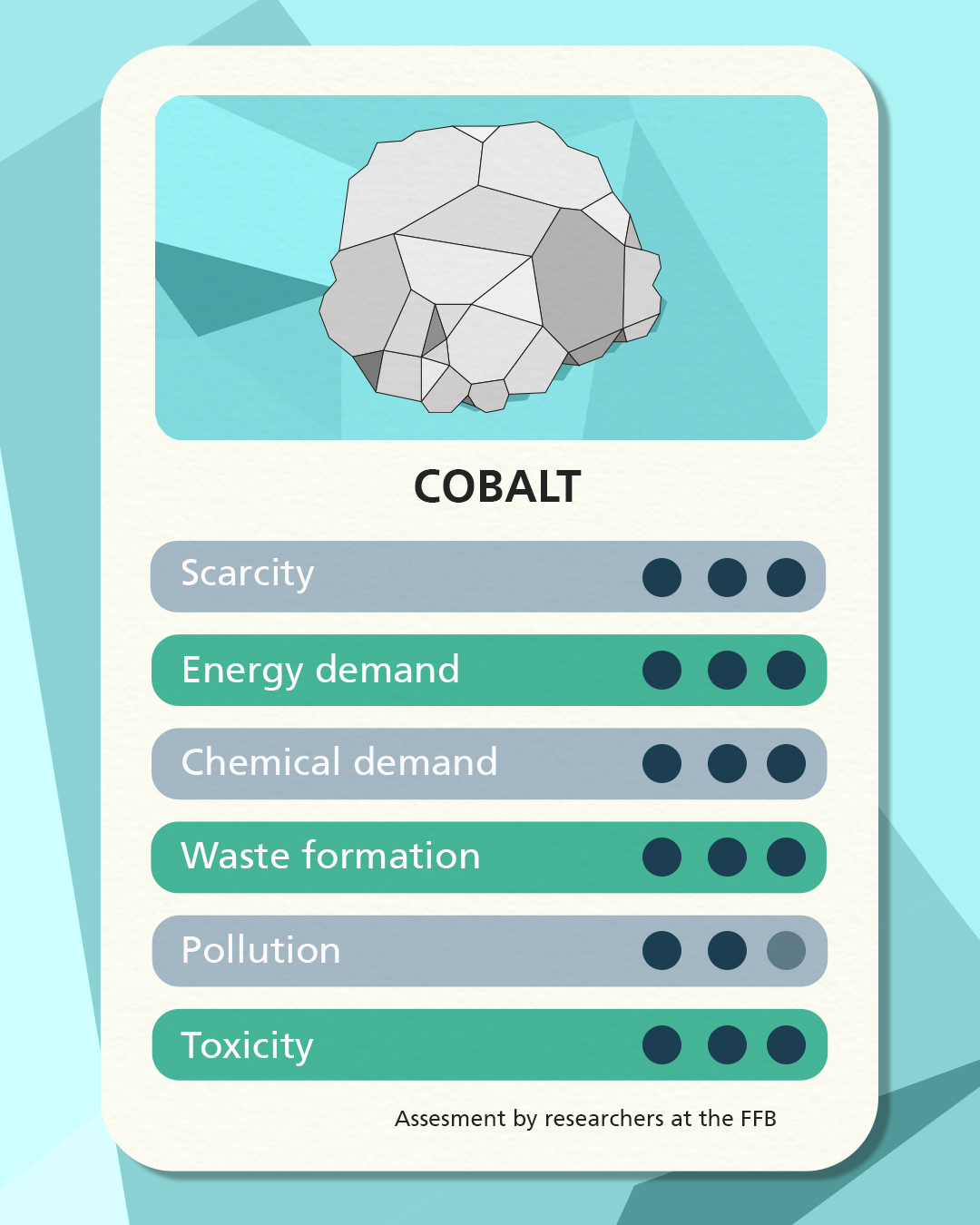

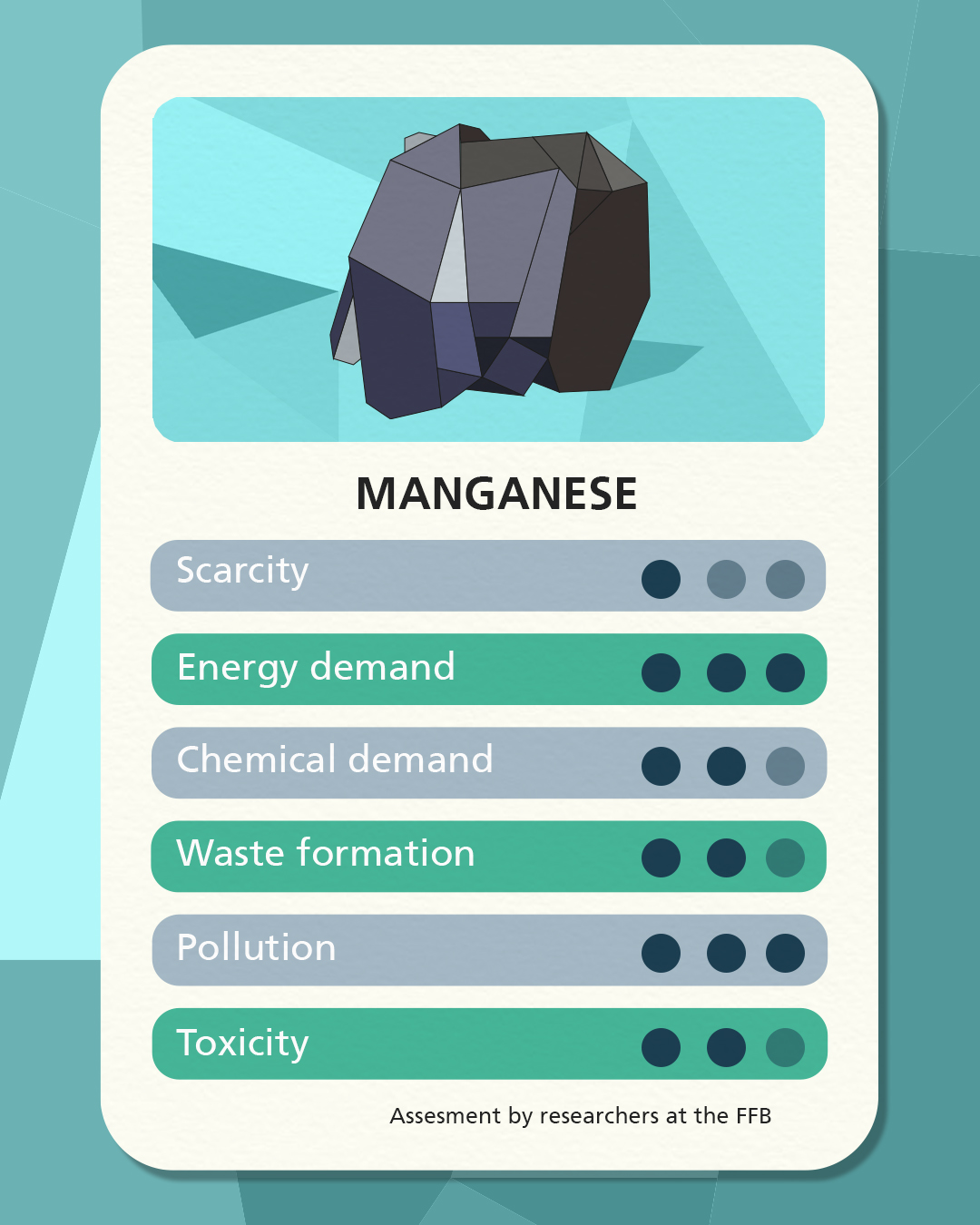

The regulation sets minimum content levels for recycled materials in batteries, which will increase over the years to promote battery recycling and the circular economy in Europe. In addition, a due diligence system has been introduced to improve the traceability of the supply and value chains. Minimum performance and durability requirements are intended to improve quality and thus the life cycle.

The Battery Passport is a core element of the EU Battery Regulation. It is intended to enable complete documentation of the battery life cycle from production to use and recycling. This creates a framework for benchmarking and minimum standards. Basic information, including technical data, is recorded in the battery passport. Data on sustainability and responsibility in the supply chain, such as greenhouse gas emissions, working conditions during raw material extraction [1], battery condition determination, repair and recyclability are essential. This information is digitally standardized and can then be accessed and updated via an infrastructure. The aim is to make the battery passport mandatory at the beginning of 2027.

[1] However, this only applies to a limited extent: companies in the supply chain must provide evidence of a due diligence policy and plans for identifying and eliminating social and environmental risks in the supply chain.