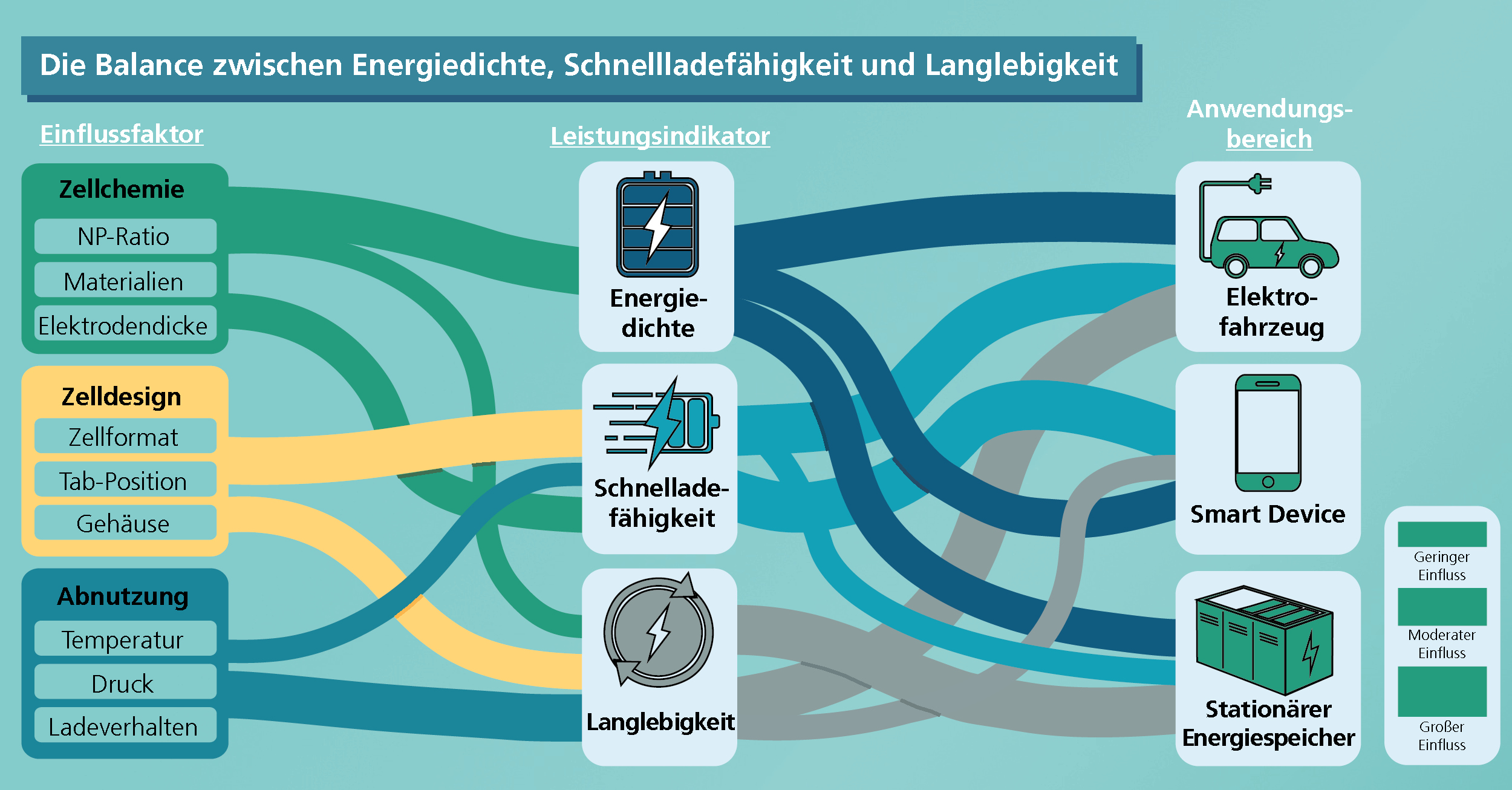

Every electric vehicle driver dreams of a battery that is quickly rechargeable, has a long range, and can be used for decades. However, it is challenging to combine these requirements because of their different influencing factors. In the third blog post of our "SkillandScaleUp" information campaign, we focus on the three most important performance parameters that determine the right cell choice depending on the area of application: Energy density, fast-charging capability, and cycle stability.

Skill and Scale up: Balancing fast-charging capability, energy density and longevity

Energy density

Probably the most important performance indicator of a battery cell is its energy density. It denotes the storage capacity ratio to voltage, i.e. the amount of energy per volume. When batteries are manufactured, the energy density decreases because inactive components such as the housing are added to the active material responsible for the energy. Caution is needed here: Energy density should only be compared at the same system level, e.g. cell to cell, material to material, or electrode to electrode.

The cell chemistry in particular determines the energy density. Here, for example, the ratio of anode to cathode capacitance plays a role, which is referred to in technical jargon as the N/P ratio. The smaller it is, the higher the energy density. It becomes dangerous when there is more lithium in the cell than can be absorbed by the anode because then lithium plating occurs. To prevent this from happening, in real cells the anodes are always designed larger, i.e. with an N/P ratio greater than 1. However, the excess anode material does not contribute to the cell's energy, but is only there for safety. Therefore, it is best to keep the excess as small as possible. Regarding cell design, optimal space utilization in battery packs and larger cell formats can contribute to higher energy density. Batteries with high energy density can store more energy but often require longer charging times to be fully charged.

Fast charging capability

In a rapidly changing world, speed and time savings are becoming decisive factors in all areas of life. From smartphones to electric cars and regenerative power generation, the ability to use energy quickly and efficiently plays an important role in choosing the right battery type for the application. The fast-charging capability is largely determined by the cell design and structure.

In cell design, the cell size, the conductivity of the cell components, the electrode thickness, and the design of the current collectors influence the charging speed. The current distribution within the cell can be influenced by the number and arrangement of the current collectors (battery trays). Heat generation and distribution within the battery cell also affect fast-charge capability, especially for large cells: Heat is released both during operation and during charging. This can harm the performance of the cell.

In the cell structure, the porosity of the electrode is an important parameter for fast charging capability, since a high and uniform porosity ensures good, i.e. in this case fast, ion transport. This works in both directions: The lithium ions can be released quickly - the battery is powerful - and recharged quickly. However, the more porous the electrode, the lower the energy density. Here, therefore, a balance must be struck between fast-charging capability and energy density.

Cycle stability

The service life of a battery, i.e. over how many charging cycles it retains constant performance, is referred to in technical jargon as cycle stability. To determine this, tests are carried out in the laboratory to determine how often the battery can be charged and discharged until it retains only 80 percent of its capacity. In addition to cell-chemical factors, the battery's usage behavior in particular is crucial for high cycle stability. Good charging and temperature management during use, as well as technical cleanliness in the manufacturing process, have a positive effect on battery life.

Fast-charge capability and cycle stability are in a tense relationship: On the one hand, the number of charge cycles a battery undergoes can influence its fast-charge capability. On the other hand, the material wears out over time, and the protective layer on the electrode surface - the so-called SEI (Solid Electrolyte Interphase) - continues to grow. This can slow down the reaction rate of the electrodes and thus reduce the charging speed. On the other hand, fast charging is potentially more likely to lead to high heat generation and thus carries a higher risk of undesirable side reactions.

Overall, there is a trade-off between energy density and cycle stability. Batteries with high energy density may have a shorter lifetime and are more susceptible to capacity loss during charge/discharge cycles. Manufacturers of batteries and battery systems are working to optimize this balance to develop batteries with sufficient energy density while maintaining good cycling stability, especially for applications where longevity and reliability are critical.