Situation und Motivation

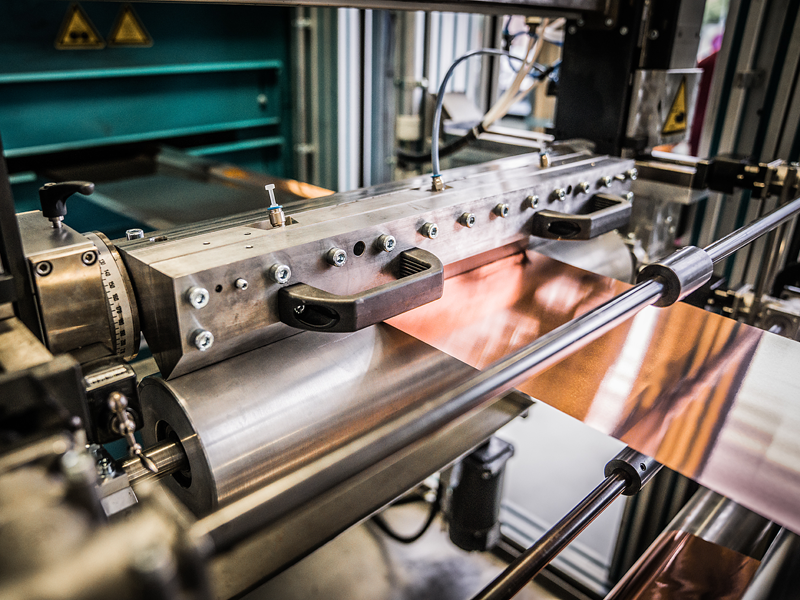

The Sovema Group's Solith business unit develops equipment for both laboratory-scale pilot lines and medium to large-scale automated production facilities. To further strengthen its competitive position, Sovema Group (Solith) is looking at expanding its product range for lithium-ion battery cell assembly. Sovema (Solith) is expanding its product range with a highly productive electrode foil-cutting system.