Sustainable battery production starts with recycling

Understanding, evaluating and optimizing processes together

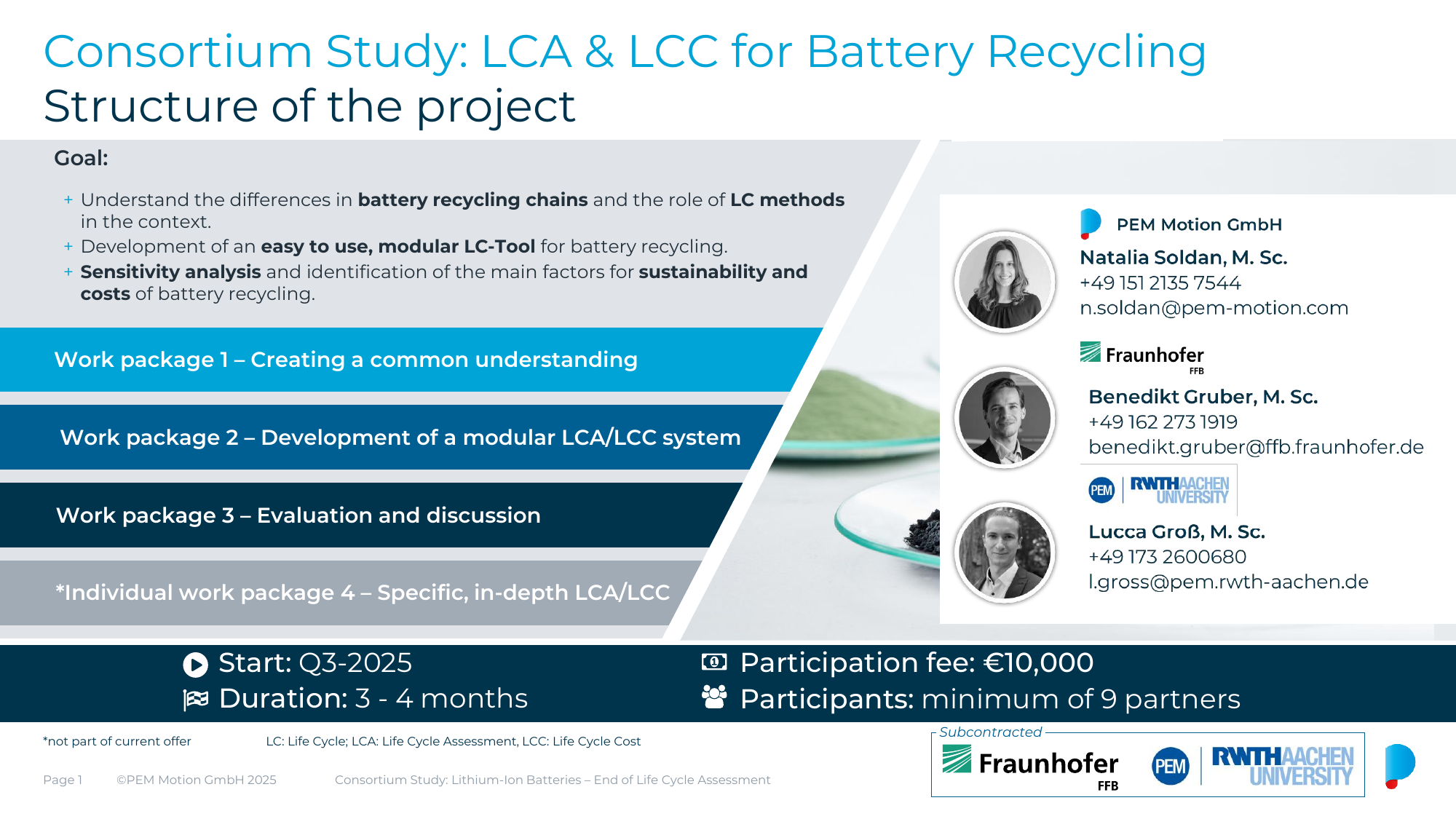

Through the consortium study "End-of-Life Cycle Assessment," we provide companies in the recycling value chain with a comprehensive ecological and economic analysis of their process chains. The goal is to establish a solid basis for decision-making that promotes more sustainable battery recycling.